We’ve all seen empty supermarkets shelves recently, waited much longer than usual for an online delivery, or experienced port and shipping problems. It’s fair to say that “lean supply chain” and “just in time” delivery are now dead. Now it’s all about digital twins, supply chain resilience, having contingency and safety stock policies, and more. Historically, safety stock calculations were based on demand volatility and target service level. Now they need to take into consideration other risks: volatility of supply, shipping disruptions, etc. Ultimately, this is going to mean holding more stock, which equals working capital, which comes at a cost. As interest rates start to raise globally this is only going to get more expensive. Proper scenario planning can solve this.

Two quotes relevant to scenario planning that come to mind:

The planning fallacy is that you make a plan, which is usually best-case scenario. Then you assume that the outcome will follow your plan, even when you should know better -Daniel Kahneman

In the business world, the rear view mirror is always clearer that the windshield- Warren Buffett

Scenario planning gives you foresight

What I take from both of these quotes is that we really need to think about how we turn that rear view mirror around and create foresight through scenario planning instead of operating only from hindsight after the fact.

We all know our baseline plan is unlikely to eventuate with the real world volatility hitting hard and causing disruptions. It’s therefore important to build contingencies into our plans. This means we need to have a good scenario planning capability.

A comprehensive and robust scenario planning capability is important for two reasons:

Envisaging what might happen and then preparing contingencies for this

Responding quickly to what has happened and re-planning in a timely manner

Good scenario planning means your baseline plan can be run efficiently (in 5-15 min) giving you the ability to replicate this quickly and run not just one scenario but multiple in order to evaluate and develop response plans for multiple outcomes.

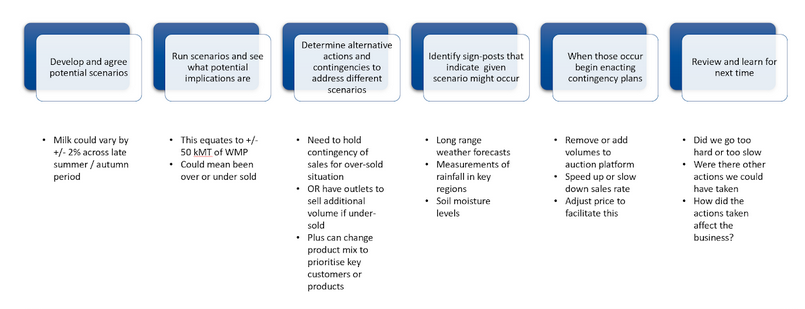

The below diagram outlines a process for scenario planning and illustrates this with an example

Advanced supply chain scenario planning is a cornerstone of our scAIcloud® platform with key features being you can batch run multiple scenarios at the same time. Our cloud infrastructure means you are not impacted by run time as more server power is brought online. Lastly, once the scenarios are complete you can compare results in diagnostic dashboards within platform, again saving time (vs extracting and analyzing elsewhere) enabling you to react faster.

In summary three things to take away about supply chain scenario planning are

- Digitizing your supply chain is critical to responding more rapidly

- Advanced scenario capabilities allow you to prepare for unknowns

- You must build in contingencies and signposts for when these plans will be enacted

Interested in hearing more about how we tackle scenario planning?

Sign up for our webinar on July 5th: Whipping Your Scenario Planning Into Shape